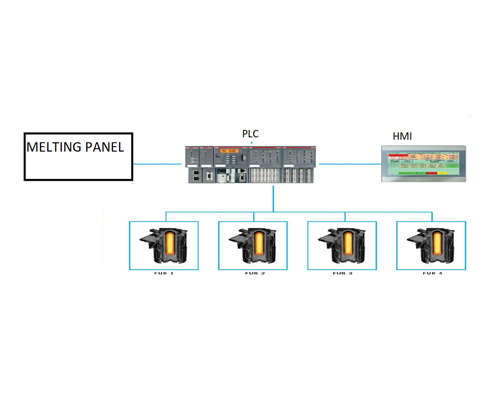

Melt Manager With & Without Load Cell

Working Procedure

- It operates energy Vs Wight.

- Actually our system to work like a semi automation. our machine to push the operator to do on the process schedule.

- It will help where we are in the performance. Based on that data we will make a production schedule or make a preventive maintenance schedule.

- If furnace run more time to cap volt melt manager will reduce the power and given the alarm to melter for speed charging.

- Furnace reached maximum energy melt manager provide the signal to operator ready to tap.if melter not to tap the metal Melt manger goes to holding mode.

- Wight value Entered by melter.

Benefits

- To avoid super heat.

- During Cap volt time Melt manager controlling the power to improve our performance.

- Auto sintering, Data logging, Trends.

- We will provide the timing signal to operator when will ready to take the sample and ready to tap.

- If we work our systematic manner unit will save the energy Minium 5 to 10 Unit per ton maximum based on the customer site.